Do Traditional Cables Always Fall Short? Servo Cables Are the Key to Stable Servo Equipment Operation.

In the welding workshops of automobile factories, robotic arms swing at high frequencies with sparks flying; in cold chain warehouses, AGVs shuttle rapidly in -20℃ environments. In these common industrial scenarios, problems with traditional cables often slow down production subtly:

Some have inadequate shielding design, leading to signal distortion under electromagnetic interference from inverters and motors. This causes inaccurate motor positioning and speed fluctuations, increasing rework costs.

Some PVC sheaths cannot withstand oil contamination, high or low temperatures. They harden and crack after short-term use, requiring frequent shutdowns for cable replacement.

Others have overly thick conductors and insufficient flexibility, easily breaking in high-frequency motion scenarios like cable chains or robot joints, resulting in frequent equipment downtime.

Zhaolong’s LONGFLEX® servo cable series is specifically designed to address these issues, supporting more stable equipment operation.

High-Flexibility Cable Selection for Cable Chain Bending Scenarios

Scenario Pain Point: The cable chain systems of automated production lines must withstand bending several times per minute or even per second. Ordinary cables experience core wire breakage or sheath cracking after 100,000 to 500,000 cycles, causing sudden shutdowns of automated equipment.

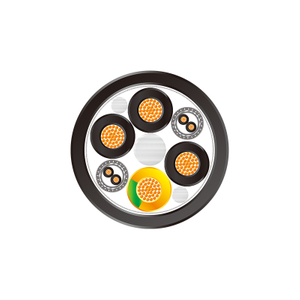

Solution: Zhaolong’s LONGFLEX® servo cable series, including models SERVO 312 CY, FD 320 CY, FD 320 CP, FD 330 CP, and FD 340 CP, all feature high-flexibility designs but differ in mechanical performance:

Performance Indicator Specification

l Cable Chain Lifespan FD 330 CP: ≥10 million cycles; FD 340 CP: 5-10 million cycles; FD 320 CY/CP: 3-8 million cycles; 312 CY: 1-3 million cycles

l Minimum Bending Radius FD series (320 CY, 320 CP, 330 CP, 340 CP): 7.5×outer diameter; 312 CY: 12.5×outer diameter. All adopt miniaturized design with small outer diameter for flexible wiring.

Selection Guide:

l For ultra-high-frequency motion scenarios (e.g., robotic arms), choose FD 330 CP, which uses TPEE insulation + PUR sheathing to optimize bending resistance.

l For fixed applications or low-speed motion scenarios, choose 312 CY.

Zhaolong Industrial SERVO CABLE

Material Selection and Adaptation Guide for Oil-Contaminated & Extreme Temperature Environments

Scenario Pain Point: Robot sheaths in automobile factories swell due to long-term contact with lubricating oil; AGV sheaths in cold chain logistics become brittle and crack in low temperatures.

Solution: All Zhaolong LONGFLEX® servo cable series meet the temperature range of -40℃ to 80℃ (for fixed applications), but differ significantly in material:

l Feature Specification

l Sheath Material FD 320 CP, FD 330 CP, FD 340 CP use PUR sheathing, offering better oil resistance and hydrolysis resistance.

l Low-Temperature Resistance For mobile applications: FD 330 CP withstands -25℃; other models: 312 CY/320 CY (-5℃), 320 CP/340 CP (-20℃).

Selection Guide:

l For oil-contaminated and humid environments (e.g., automobile factories), choose FD 320 CP or FD 330 CP (halogen-free PUR sheathing).

l For scenarios with high environmental protection requirements (e.g., food processing), prioritize FD 320 CP, FD 330 CP, and FD 340 CP.

An Excerpt from the Test Reports of Zhaolong Servo Cables

An Excerpt from the Test Reports of Zhaolong Servo Cables

The "Signal Defense Battle" Beside Inverters: Confronting Electromagnetic Interference

Scenario Pain Point: High-frequency interference from the superposition of servo drives and inverters causes signal loss.

Solution: All Zhaolong LONGFLEX® servo cable series are equipped with high-coverage tinned copper shielding, providing excellent anti-interference performance. This effectively reduces interference to surrounding components and external interference to the cables themselves.

Standard Compliance: All Zhaolong LONGFLEX® servo cable series meet UL standards.

Selection Guide:

l For servo power applications: Choose 312 CY/FD 320 CY/FD 320 CP/FD 330 CP series.

l For encoder applications: Choose FD 340 CP series.

Zhaolong Industrial SERVO CABLE

The "Every Inch Counts" Challenge in Compact Spaces: Inside Control Cabinets

Scenario Pain Point: Drive-control integrated cabinets have narrow spaces, and cross-wiring of multiple cables causes heat dissipation risks.

Solution: Zhaolong Interconnect’s latest servo composite cables.

lSingle-Cable Design: Adopts an integrated single-cable structure, combining power cables, data signal cables, and brake control cables. It accurately meets the connection needs of mainstream drive-control integrated servo systems and significantly reduces space occupation for different scenarios.

lTwo Structural Types: The cable offers two structural types—fixed wiring type and high-flexibility type. The fixed wiring type is suitable for ordinary non-motion equipment; the high-flexibility type is adapted to dynamic scenarios such as cable chains and robotic arms.

lSafety Certification: The entire cable complies with IEC 60332-1-2 flame retardancy test. It maintains good safety performance and electrical reliability even in compact spaces and complex electromagnetic environments.

lData Transmission: The data transmission part meets the CAT5e communication standard, enabling high-speed and stable transmission within 50 meters in standard test environments.

lConnector Compatibility: Supports M23+IX hybrid connectors, meeting the synchronous connection requirements of power and Ethernet signals.

lWide Applications: Widely used in robotic arms, precision transmission systems, and automatic packaging/printing/assembly lines, providing efficient, stable, and compact connection experiences.

Selection Guide: For other servo cables, prioritize the FD series (small bending radius) for compact cabinet wiring. For halogen-free environmental protection requirements, choose FD 320 CP, FD 330 CP, and FD 340 CP.

One of the Partial Test Reports of Zhaolong Servo Cables

Conclusion: Building a "Stable Defense Line" for Industrial Connections

From robotic arms with welding sparks to cold chain AGVs at -20℃, from signal interference beside inverters to the "every inch counts" challenge inside control cabinets—every problem in industrial scenarios tests the reliability of connection solutions.

With four core capabilities—high flexibility and bending resistance, oil and corrosion resistance, strong anti-interference, and efficient integration—Zhaolong servo cables build a "protective network" for the stable operation of servo systems.

nChoose the 312 CY series for low-speed motion power cables.

nChoose FD 330 CP for ultra-high-frequency motion power cables.

nUse PUR-sheathed models like FD 320 CP or FD 330 CP in oil-contaminated environments.

nChoose the FD 340 CP series for encoder signals.

Selecting the right cable not only reduces failure rates but also provides "insurance" for production line efficiency and equipment lifespan.

The details of industrial connections determine production precision. Let Zhaolong servo cables be the "invisible guardian" of your equipment, supporting efficient and stable production at all times!

English

English

简体中文

简体中文