According to data released by the General Administration of Customs of China, in the first three quarters of 2025, China's industrial robot export value increased by 54.9% year-on-year. This indicates that Chinese-made robots, with their increasingly diverse application scenarios, are continuously expanding their influence in the global market.

In this context, the core challenges faced by industrial robots have become increasingly prominent: their joint cables must maintain signal integrity and stability even under complex operating conditions such as tens of millions cycles of bending cycles and high-frequency electromagnetic interference. The R&D of Zhaolong robotic cables is precisely focused on addressing these challenges, committed to providing reliable "invisible motion guardians" for high-end equipment through material and structural innovations.

Zhaolong Robotic Cables: Targeted Solutions for Application Challenges

Zhaolong robotic cables specialize in solving connection challenges in industrial automation. With deep expertise in design and manufacturing, our products are custom-developed for motion scenarios, widely compatible with industrial robots and robotic arms. They aim to address issues such as complex equipment cabling and insufficient operational stability, delivering reliable connectivity for automated production.

I. Core Performance: High-Frequency Motion Adaptability & Compliance Safety

The core advantage of Zhaolong robotic cables lies in their high durability and flexible adaptability, with key features directly addressing application pain points:

High-Frequency Motion Endurance: Capable of withstanding over 10 million torsion cycles, meeting the long-term high-frequency motion requirements of robotic arms and reducing cable replacement frequency.

Compact Bending Design: Minimum bending radius of only 3D(D=cable outer diameter) for fixed applications, and 5D for mobile applications, suitable for tight spaces such as robotic joints.

Safety & Compliance Certifications: Fully compliant with UL safety standards and RoHS environmental standards, ensuring both operational safety and environmental friendliness, while meeting industrial scene access requirements.

II. Material Selection: Balancing Performance & Scenario Adaptability

Exceptional performance stems from rigorous screening and precise matching of core materials. Our robotic cable materials are carefully selected to balance conductivity, structural strength, and environmental resilience, offering multi-scenario adaptive solutions:

Jacket Material Options: Two specialized high-strength jackets are available to match different operating conditions:

PVC Jacket: Cost-effective, with oil resistance and flame retardancy, suitable for conventional industrial environments.

PUR Jacket: Outstanding wear resistance, oil resistance, and low-temperature performance, capable of withstanding harsh conditions such as oil contamination and sub-zero temperatures.

III. Additional Advantages: Complex Condition Resilience & Stable Transmission

Beyond core performance, the cables feature multiple practical characteristics to enhance scenario adaptability:

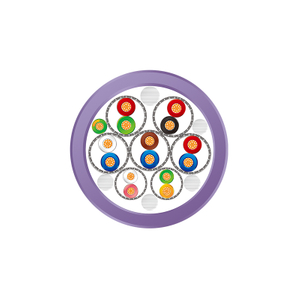

Anti-Interference Design: Employs an ultra-high coverage shielding structure to effectively resist electromagnetic interference generated by inverters, motors, and other equipment, ensuring accurate and stable signal transmission.

Multi-Environment Tolerance: Combines resistance to torsion, bending, abrasion, and extreme temperatures (-40°C to 80°C), making it suitable for diverse complex conditions such as welding workshops, cold chain warehouses, and precision machine tools.

Long-Term Durability: Materials and structural designs prioritize "low loss" to minimize performance degradation during extended use, reducing equipment maintenance costs.

Integrated Solution: Simplified cabling, Cost Efficiency

To address the pain points of complex cabling and limited space in industrial equipment, Zhaolong introduces an integrated connection solution (One Cable Solution):

Function Integration: Combines power transmission, signal transmission, and data transmission into a single cable, replacing traditional parallel multi-cable cabling methods.

Core Value: Simplifies cabling processes, saves internal installation space within equipment, and reduces comprehensive costs related to cable procurement, installation, and maintenance, thereby improving project implementation efficiency.

Product Classification: Comprehensive Coverage of Diverse Needs

Products are categorized by "distribution location" and "function type" to precisely match different application scenarios:

Robot Body Cables: Designed with flexibility and higher tensile strength requirements, suitable for high-frequency motion in body joints.

Control Host-to-Body Connection Cables: Ensure stable signal/power transmission between the host and the robot.

Controller-to-Teaching Pendant Cables: Adapt to the mobile operation needs of teaching pendants, balancing flexibility and durability.

Our robotic cables cover a full range of products for power supply, servo drive, and data communication (including power cables, servo cables, encoder cables, data cables, and signal cables). They support flexible selection based on equipment functions, meeting comprehensive requirements for stable power supply, precise control, and reliable communication in industrial robots.

Principles for Robotic Cable Selection: Practical Guidelines Based on Scenarios

Selecting industrial robotic cables requires precise alignment with three dimensions: "scenario conditions → performance parameters → compliance standards" to avoid equipment downtime or cost waste caused by selection errors. Based on Zhaolong’s product features, the following practical principles are recommended:

1. Scenario Adaptation: Locking Core Configurations Based on Operating Conditions

Environmental pressures (humidity, oil contamination, abrasion) in different industrial scenarios directly determine the jacket material and structural design of the cables:

Low-Temperature/Oil-Contaminated Scenarios (e.g., Cold Chain Warehouses, Automotive Welding Workshops)

Pain Points: Jacket brittleness at -40°C, swelling due to oil contamination.

Solution: Select PUR-jacketed models (e.g., FD 330CP/FD 320CP).

Low-Temperature Performance: Mobile applications down to -25°C.

High-Frequency Motion Scenarios (e.g., Robotic Arm Joints, AGVs)

Pain Points: Core wire breakage due to frequent torsion (multiple times per minute).

Solution: Choose high-flexibility models (e.g., FD 938CY/FD 330CP).

Torsion Life: ≥10 million cycles (robotic arms), 3–8 million cycles (AGVs).

Bending Radius: 3D (fixed applications), 5D (mobile applications).

2. Performance Matching: Defining Parameters Based on Motion Intensity & Precision Requirements

The motion frequency and operational precision of robots determine the corresponding "mechanical endurance" and "transmission stability" metrics of the cables:

High-Torsion/Bending Scenarios: Focus on "torsion life" and "bending radius". For ultra-high-frequency motion (1–2 torsions per second, e.g., robotic arm joints), select models with torsion life ≥10 million cycles and fixed-application bending radius of 3D (e.g., FD 938CY). For medium-low-speed mobile scenarios (e.g., AGVs), opt for models with 5D bending radius and 3–8 million cycle torsion life to balance performance and cost.

High-Precision Operation Scenarios: For tasks like semiconductor wafer handling or precision assembly, prioritize "anti-interference capability" — select Zhaolong cables with ≥85%–90% shielding coverage to resist electromagnetic interference from inverters and motors, ensuring positional signal stability.

3. Compliance & Service Assurance: Mitigating Risks Through Standards & Customization

Industrial scene entry requirements and post-maintenance needs must be addressed during the selection phase:

Compliance Thresholds: Prioritize multi-standard certified products — ensure compliance with UL safety standards (to avoid electrical risks), RoHS environmental standards (for export needs), and IEC 60228/IEC 60332 flame retardancy requirements to prevent production line acceptance issues.

Customization Services: For non-standard scenarios (e.g., special lengths, irregular cabling), choose brands with flexible customization capabilities. Zhaolong offers length customization, special jacket adaptations, and supports integrated one-cable solutions (power + signal + data) to reduce post-installation cabling modification costs.

Empowering Industrial Automation Upgrades with Reliable Connectivity

The stable operation of industrial robots in complex scenarios consistently relies on the reliability of their cables. Zhaolong robotic cables provide foundational support through three core capabilities: tens of millions of motion cycles, full-environment endurance, and integrated cost reduction. Backed by the intelligent manufacturing capabilities of our Deqing production base and our CNAS-certified laboratory (certificate No. L12345), we will continue to deepen research in high-reliability cable technologies, delivering stable, high-speed connectivity for industrial robots.

English

English

简体中文

简体中文